Pallet stacking patterns

In the first article, we talked about the best way to stack a pallet. In this second part of our four-part series of articles on pallet loading, we will discuss the fundamentals of what the correct layout is to ensure stability during transport, storage, and minimize the risk of damage to the products.

Source: https://estanteriasrecord.com/tipo-mercancia/paletizacion-convencional

For this purpose, different stacking patterns are available to optimize available space, reduce shipping costs, minimize loading and unloading time, and maximize the handling efficiency of goods.

In addition, we will discuss how to choose the correct stacking pattern according to the characteristics of the products as well as the transport and storage conditions to ensure efficient pallet load management.

Below are some of the most common pallet stacking patterns:

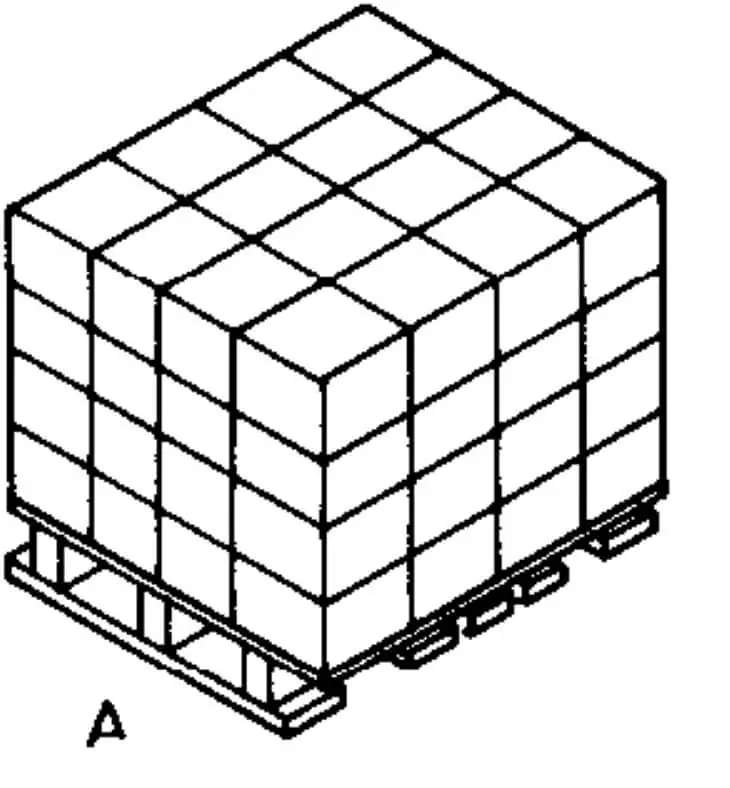

Block pattern

A « block pallet pattern » refers to the arrangement of pallets in rows and columns, typically in a uniform square or rectangular design, to maximize storage efficiency and facilitate access to products in warehouses or during transportation. This approach is essential for efficient inventory management and logistics optimization in storage and distribution environments.

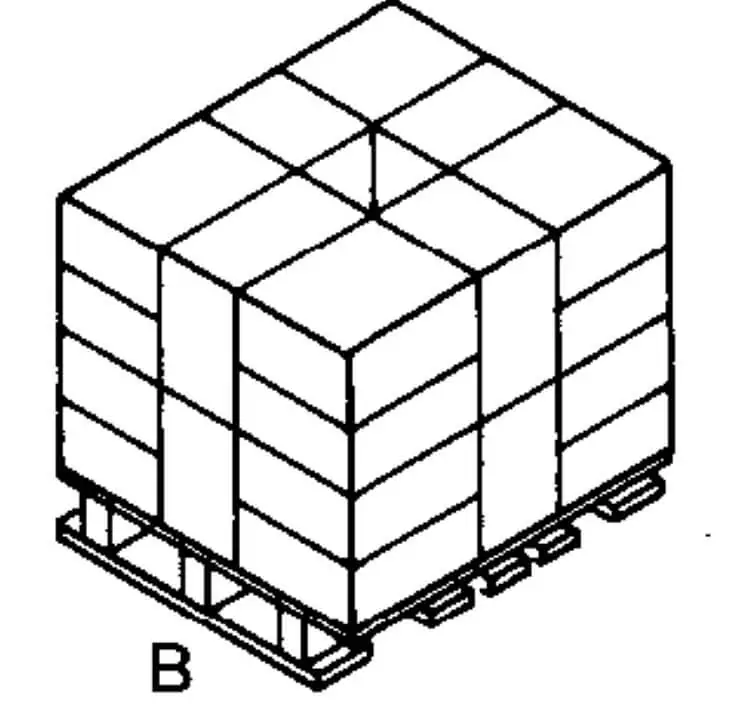

Split Block pattern

Loading pallets in split block involves dividing a storage or transport space into two sections to efficiently organize and separate different products. This facilitates inventory management and ensures accurate deliveries. It is helpful in warehouses and distribution. By clearly demarcating different product categories or groups, the Split Block pattern contributes to efficient storage, retrieval, and distribution processes, particularly in complex supply chain environments.

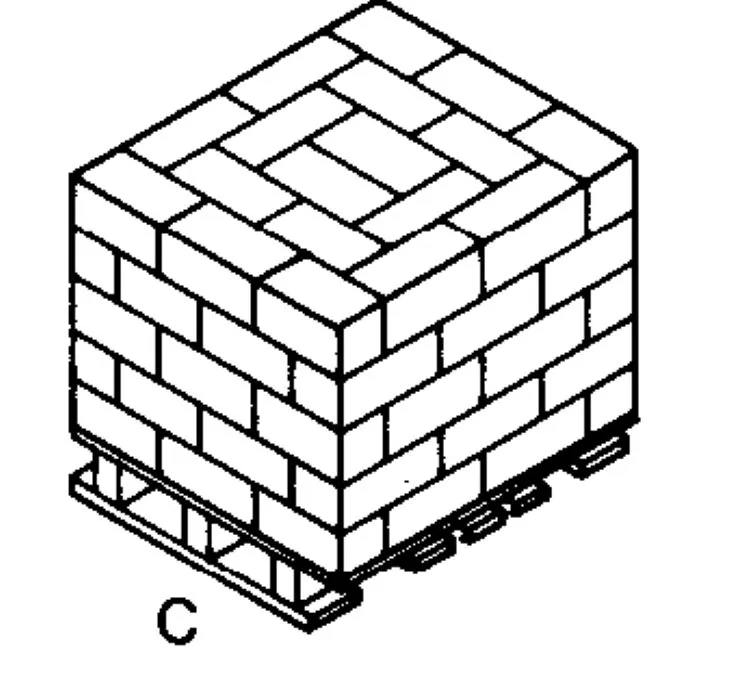

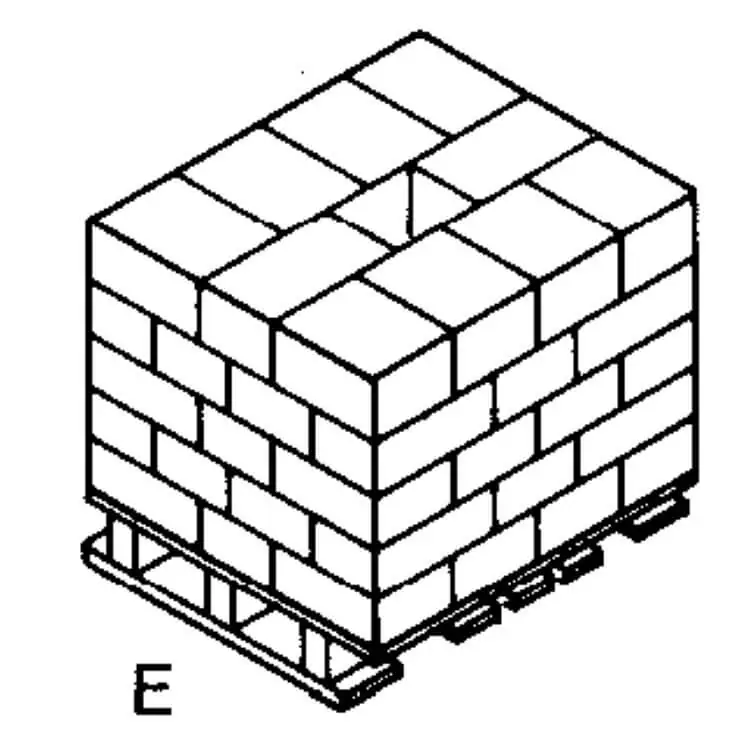

Brick pallet

A « brick pallet » is a specialized pallet designed for the transportation and storage of bricks. These pallets are typically smaller in size and reinforced to handle the weight and dimensions of bricks safely. They are stackable, allowing for efficient storage in construction sites and warehouses. Brick pallets are essential for the organized transport and storage of bricks in the construction industry, providing stability and support to prevent damage during handling and transportation.

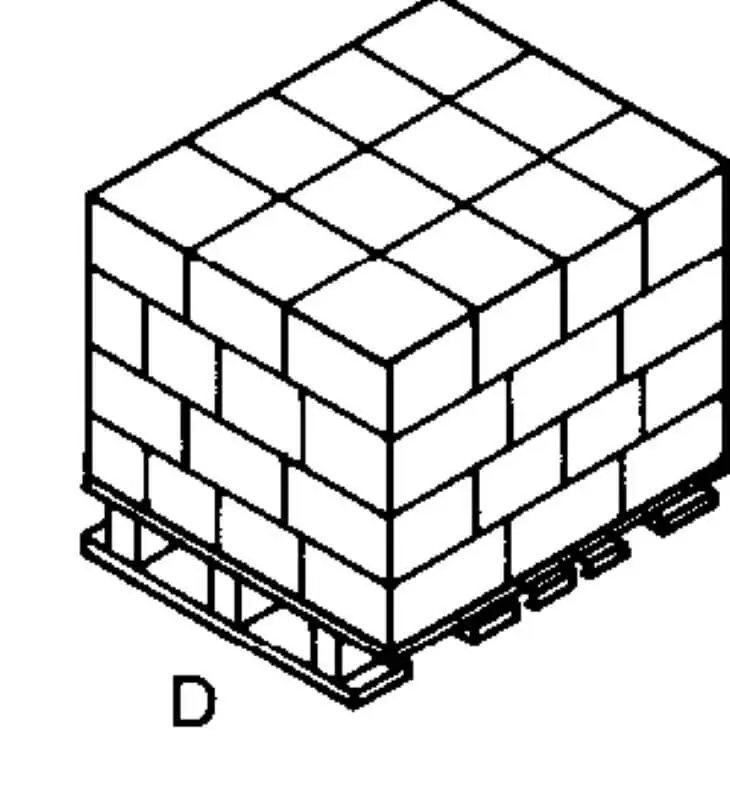

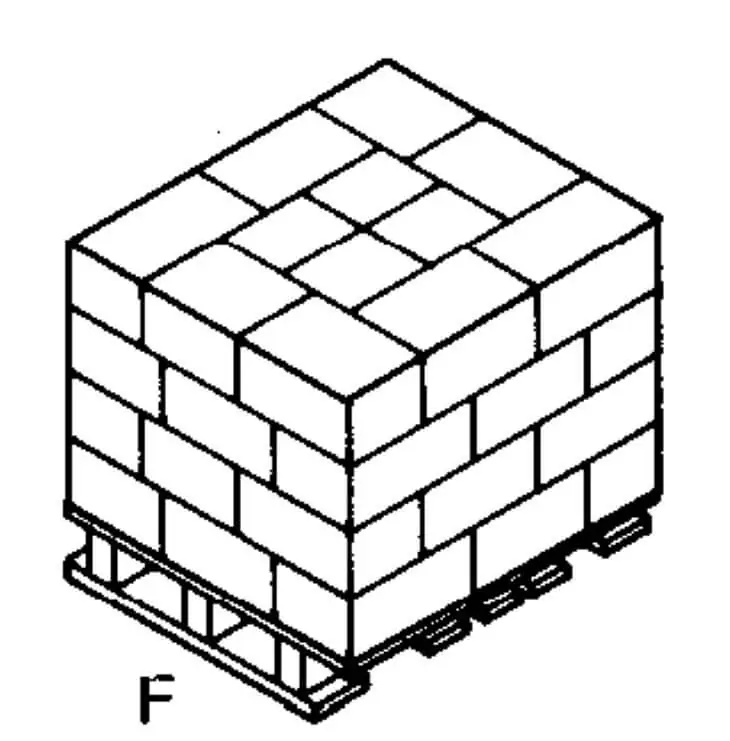

Row pattern

In this type of palletization, products are organized in rows on a pallet, typically with each row containing the same or similar items. This method is often used for items that are uniform in size and shape, such as boxes or cases of goods. Here are some key points about row palletization:

Split row

A « split row pallet » is a palletization technique that involves arranging products on a pallet in two separate rows, often with a gap in between. This method is commonly employed to efficiently segregate and organize different types of products on a single pallet, aiding in inventory management as well as simplifying loading and unloading procedures. It is particularly valuable in warehouse distribution settings where precise product categorization as well as separation are essential for optimizing logistics and supply chain operations.

Pinwheel pattern

The « pinwheel pattern » in logistics and palletization refers to the strategic arrangement of items on a pallet in a radial or spiral configuration, similar to the shape of a pinwheel. This approach is employed to optimize space utilization on the pallet, mainly when dealing with irregularly shaped items or when aiming to enhance stability and minimize wasted space. It contributes to the efficient loading, storage, and transportation of goods, making it valuable in scenarios where space efficiency is crucial.

Using EasyCargo, we can apply different restrictions within our loading plan such as no tilting, no stacking, and no rotating. You can also create groups for a better division of your items, and this will finally help you transport the items in the way you want while doing so in a safe way. Learn more about how you can benefit from this software by trying it for free here.

Now that we have covered the different pallet stacking patterns and you have an idea of which pattern to choose as well as which one best suits the type of load you are handling, then we will move on to our next article where we will talk about the difference between column stacking vs interlocking stacking.

Don’t miss the third article in our four-part series on pallet loading!